When purchasing used plastic injection molds, there are different issues that you need to be aware of to minimize the production issues that are associated with using the used molds. Potential production issues with the used molds include bad part quality, slower cycle times, molding lower than full cavitation, as well as machine stoppages due to the bad part ejection.

When purchasing used plastic injection molds, there are different issues that you need to be aware of to minimize the production issues that are associated with using the used molds. Potential production issues with the used molds include bad part quality, slower cycle times, molding lower than full cavitation, as well as machine stoppages due to the bad part ejection.

Molding Machine Damages

Another major issue is that molding machine can be damaged due to used moldings. Used plastic molds are typically in bad condition and this can cause broken tie bars, platen wear, and even broken toggle pins.

9 Step Guide to Purchasing the Used Molds

In order to get the most from the used plastic injection molds, there are some questions that you will need to ask before you purchase them.

1. Ask to see the mold in action or ask for samples. This is the only way that you will get an accurate idea of the cycle time and the quality.

2. Ask for samples from all of the cavities. Weigh the samples and measure them for their thickness. This information will offer you a more accurate picture to the condition of your mold. Any of the large variations in the cavity, then you will know that you should not purchase these.

3. If the mold has a cold runner, then ask for a sample for a runner. This is needed in order to accurately measure the size of the shot. Also, measure the runner thickness and then compare it to the thickness of the part wall.

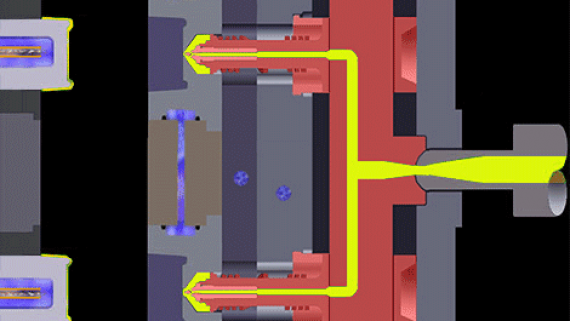

4. Ask for some pictures of both the moving and the fixed sides of all of the used injection molds that you may be interested in purchasing. Pictures will help give you more information about the mold condition like any unusual wear patterns, which would lead to poor part quality. It will also give you the idea of the mold design.

5. Ask for the material specifications. The type of aluminums, steels, or the copper alloys that are used in the mold construction. It will heavily influence the life of the mold and the ability to repair or even modify it.

6. Ask for the age of the mold. The age will give you an idea of the possible future issues.

7. Ask for the drawings and the mold design drawings. It will make it easier to modify or repair it if you need too.

8. Ask who made the molds. If an injection mold manufacturer with a great reputation made it, then it will give you some confidence in purchasing the molds.

9. Other questions that you may ask include the plastic material and the mold size to make sure that it is compatible with the machinery that you have.