Plastic moulds, categorized into two primary types (cold runner and hot runner) are the beginning of each plastic piece you see. If you have zero knowledge about these two types, your plastic injection molder should be able to give you information that will allow you to understand cold runner moulds and hot runner moulds and even know their benefits and costs. However, it is still bested if you make your own research first so you can have your own view before talking to the molder and before coming up with a decision about which is suitable for your project:

Cold Runner Moulds

These have two to three plates, which are clutched in the mold base. Using sprue, the plastic is injected into the cold runner mould, going to the parts in the cavity. The parts and the runner system are joined in the two plate moulds. An ejection method is utilized to make the pair from the mould part. Remember when you were just a kid and you were assembling a robot or a car? Surely, you have noticed that parts of your toy were not separated from the runners. It was you who were the one that separated them. On the other hand, in three-plate plastic moulds, only the parts are ejected as the runner is placed on a different plate.

In this process, no plastic is wasted because it is recycled and reground.

Advantages:

- Quick to modify colors

- Production and maintenance are cheaper

- Rapid cycle times (particularly if the systems make use of robotic assist to eliminate runners)

- Can accept a wide range of polymers (engineered and commodity)

Disadvantages:

- Slower cycle times

- Runners may have plastic waste, specifically when they are not recycled and reground

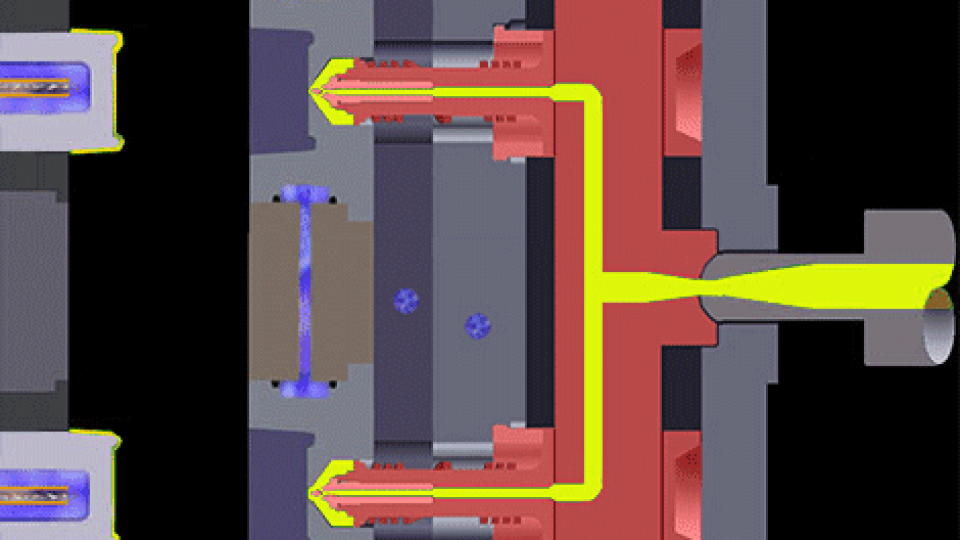

Hot Runner Moulds

Hot Runner Moulds

Hot runner moulds consist two primary categories: internally and externally heated systems. Externally heated systems are more suitable to polymers because they are susceptible to thermal forms. Internally heated systems, on the other hand, promote a more excellent flow control. These types of plastic moulds are comprised of two plates that are heated using the manifold system, which drives the dissolved plastic to nozzles. These nozzles fill up the part cavities. Unlike in the cold runner moulds, hot runner moulds completely remove runners thus they create no impact in cycle times.

The insulated runner is a modification of this system. Instead of heat, the insulation maintains the plastic in its melted condition. It can only accept small numbers of plastics, particularly the semi-crystalline polymers as it carries low thermal conductivity.

Advantages:

- Eradicate runners, as well as possible waste

- Can hold larger parts/pieces

- Can make cycle times quicker

- Do not require robotics to eliminate runners

Disadvantages:

- Difficult to change colors

- Production can be expensive

- Possible downtime

- Higher cost for maintenance

- Thermally-sensitive materials are not suitable

Expert plastic injection molders can help you identify the right injection molding system best for your project. They should have complete knowledge of all types of plastic processing. They can also help you find used plastic moulds or used injection plastic moulds or they can offer you advice if these are cost-effective to use.

Updated January 2020