The success of the manufacturing process largely depends on the precision of the used plastic molds. It serves as the foundation of parts for countless of products. The choice of plastic injection molding machines is a determining factor whether production will be effective. Manufacturers must consider all aspects that go into the molding procedure. These include the types of plastic used and their reaction for each kind of material that plastic injection molds are built with.

The success of the manufacturing process largely depends on the precision of the used plastic molds. It serves as the foundation of parts for countless of products. The choice of plastic injection molding machines is a determining factor whether production will be effective. Manufacturers must consider all aspects that go into the molding procedure. These include the types of plastic used and their reaction for each kind of material that plastic injection molds are built with.

In general, there can be two categorizations for plastics in terms of fluidity – those with high viscosity and those with low viscosity. When it comes to plastic, the more free-flowing it is, the higher the shrinkage it has. The level of viscosity and rate of shrinkage are considered during the engineering and design process, as these elements change the specifications of the plastic mold.

With the use of modern CAD software, the design and measurements of the cavities are tailored for the type of resin that will be used. Usually, plastic providers indicate the features of the resins they release so that the engineers may adjust the design to accommodate stress, tension, and shrinkage, among others.

The purpose of the mold

Alongside with the considerations in the type of plastic used, manufacturers also consider the purpose of the mold. The answer to this question will determine the material to be used so that the plastic molds will achieve longevity. Should the manufacturer need them for long-term use, such as the production of key parts for their product, hardened steel must be the choice. With the use of this material, the mold will surely last even if used in high-volume productions. For short-term use, aluminum can be an option. It is cheaper in value but also durable enough for moderate production volume.

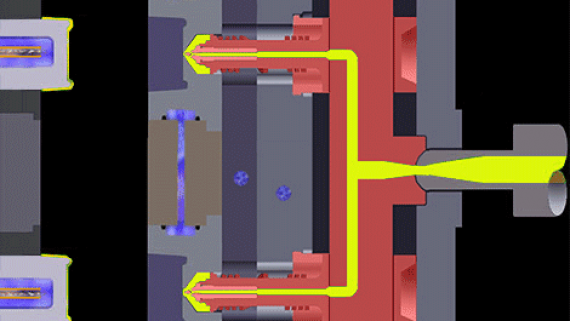

The efficacy of the entire plastic injection machine is not limited to the precision of the cavities installed. It can also be highly affected by other parts well within, such as the gates, vents, and ejection mechanism. During the production, it is the gates that allow the plastic to pass through. Their design dictates the speed of production cycles. The vents, on the other hand, are as equally important since it is thru them that air flows in and out of the machines. A badly ventilated machine can produce unwanted bubbles. Vents also aid the machine’s cooling system, and this is essential because the consistency of the temperature is indispensable for flawless production. At the end of the molding process, the parts produced are to be ejected out of the machines. The ejection mechanism must be precise at all times to avoid damage to the final output. The strength and positioning of ejector pins are calculated in accordance with the toughness and design of the plastic.

A perfectly designed molding machine results in perfectly produced parts. Efficiency, productivity, and quality will surely follow if molding machines in place are not just working, but working smart. Plastic molds are one of the most convenient tools in production. It is only right to give it the precision it needs.