StarMould Blog

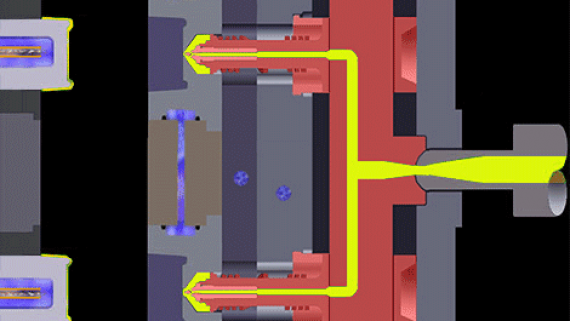

Plastic injection molding is a manufacturing process wherein plastic is injected into aluminum, or steel molds and squeezed under high pressure to come up with the desired shape of the product. The molding material is heated so that it comes in a fluid state and is injected into a mold until it hardens. The product is usually designed by industrial engineers or designers. Injection molding is mostly used for manufacturing very small to very big items or parts of cars.

There are a number of companies offering as StarMould. Companies sell either newly used molds or injection molds.

Customers have varying levels … Read More

The most widely used manufacturing process for the fabrication of plastic products is the plastic injection molding. This is due to the many products that the process can produce, and these products can vary according to their size, intricacy, and application.

This process starts by melting the plastic in a hot barrel. The melted material is then mixed and fed into the molding machine where the plastic will solidify into the final product once it cools…

Plastic moulds, categorized into two primary types (cold runner and hot runner) are the beginning of each plastic piece you see. If you have zero knowledge about these two types, your plastic injection molder should be able to give you information that will allow you to understand cold runner moulds and hot runner moulds and even know their benefits and costs. However, it is still bested if you make your own research first so you can have your own view before talking to the molder and before coming up with a decision about which is suitable for your project:

Cold Runner … Read More

Looking at buying a few plastic molds? It may seem like there are countless options out there but for working quality that won’t break the bank, buying a second hand mold is really the best way to go. Not only are these molds tried and tested to produce every time, but they are also less expensive than buying a mold brand new. With a second hand mold, you will get a product of high quality but also a product that has been previously tested.

European Molds

You do not want to buy a second hand mold from anywhere or anyone. Used moulds … Read More

When purchasing used plastic injection molds, there are different issues that you need to be aware of to minimize the production issues that are associated with using the used molds. Potential production issues with the used molds include bad part quality, slower cycle times, molding lower than full cavitation, as well as machine stoppages due to the bad part ejection.

Molding Machine Damages

Another major issue is that molding machine can be damaged due to used moldings. Used plastic molds are typically in bad condition and this can cause broken tie bars, platen wear, and even broken toggle pins.

9 Step Guide to … Read More

When you do not choose the right plastic injection molding machine, it can have dire consequences for your business. The best way to avoid this is to know what not to do when choosing a machine. Here are the main mistakes that business owners often make when buying used injection moulding machines.

Mistake #1: Purchasing Used Machines that are Faulty

When companies refurbish an injection moulding machine for resale, they do not always ensure that it works. Even machines that work may have flaws. This is the reason it is critical to choose an injection machine that has passed tests and inspections, … Read More

When designing plastic parts, you are involved in a complex task that involves many different factors. You must constantly be thinking about how the part will be used, how it will fit into other parts, and what kind of loads it will experience when it is being used. Also, a complicated subject is a process of creating the part using plastic molds and injection molding equipment. Molten plastic enters fills, and cools within the mold to form the part, and it needs to be done right the first time.

What injection molding equipment do you need to properly begin injection molding?

Injection … Read More

Today’s modern civilization is built largely on a few key materials, namely, stone, wood, metal and plastic. Although wood, stone and metals are very important in modern society, one material has been dominating our modern lifestyle: levitra online europe plastic. As a plastic injection moulder, we appreciate our trade and its origins. So, here’s a look back through the History of Plastic Moulding and see how injection moulding came to be.

In 1868, after John Wesley Hyatt was tasked by Phelan and Collander, a billiard ball making company, to find a way to make billiard balls more efficient and more … Read More

As in any manufacturing process, a custom plastic injection molding is a complicated, detail-driven and tedious project. As early as in the planning stage, there are a few important considerations to think of. These would need to be laid out in as much detail as possible. This is to ensure a clear picture of all concerned parties, especially your plastic injection mould manufacturer. A good plan also helps you manage your project timeline. So for a smooth project, keep the following factors in mind.

Budget and Cost Limitations

Information needs to be very specific and straightforward to be able for an … Read More

Have you ever thought about how useful plastic is in the manufacturing world? With the use of plastic molds, it can be turned into almost any shape. It can be used as item components, whole items, and even to package materials into containers for sale. In order to make wise decisions for your company, it is important that you understand the main methods used today for manufacturing plastic.

Blow Molding

Blow molding offers the most variations out of these types of manufacturing. Essentially, you make a hollow length of melted thermoplastic that has been pre-shaped. A mold closes around this length, known … Read More

Plastic injection molding is an efficient method of creating components and parts of plastic. Injection molding is a manufacturing process that is used to produce plastic components and parts wherein a heated material is injected into a specific mold. The molds are made of specific designs that are usually personally customized or designed by customers. It gives them flexibility and control over the output. Injection molding is usually used for molding glasses and various metals aside from plastic components or parts but it is seen as a highly effective way of producing custom injection molded plastics.

Advantages of Plastic Injection Molding

Injection … Read More

A custom plastic injection molder can easily prepare a plastic injection molding quote basing on the CAD drawing or even on a two-dimensional or hand drawing, but it is still possible that you will spend for unnecessary items if you will not give them beforehand the information you need to see in the quote. Most molders search for these things from a customer who asks for new or used plastic injection molding quote: drawing, preferred material, application, quantities and secondary operations.

Drawing – You may think that an experienced molder should already know what product developer like you will typically ask … Read More

Molds that have been built with corrosion resistant technology often have a much longer life. It able to come into contact with the plastics and water during the production without suffering from corrosive damages. This is a quality that is very important to look for in used plastic injection molds.

Before you choose a plastic injection mold for use in your factory, it is critical to take the following things into account:

• How costly the molding process will be

• Material that the mold made from

• Size of the mold

• Type of material being molded

• Present environmental conditions (i.e., humidity)

• Mold maintenance, … Read More

When it comes to maintaining the integrity of your brand, it is crucial that you get the right color for your product. Color is highly subjective and it has a huge impact on people’s physiology and psychology. It increases your product’s appeal and perceived value. You cannot rely on the human eye to judge the accuracy of colors. People see color differently even when they’re looking at the same object.

So, in order to be accurate when coloring plastics, you need to use a variety of methods especially when you’re matching physical samples. Fortunately, we have invested in an extremely effective … Read More

The success of the manufacturing process largely depends on the precision of the used plastic molds. It serves as the foundation of parts for countless of products. The choice of plastic injection molding machines is a determining factor whether production will be effective. Manufacturers must consider all aspects that go into the moulding procedure. These include the types of plastic used and their reaction for each kind of material that plastic injection molds are built with.

Some factors affect plastic molds prices. Generally, the quality influences the cost. Plastic molds made in other countries are said to be cheaper (but not too cheap); however, these involve issues about quality and lifespan. High-production makers of plastic injection molds in the US make use of the finest quality in steel for cavities and mold base. More important, they use the most recent technology in CNC machining and work with expert tool makers who have sufficient knowledge and expertise in producing molds that meet the standards in the highest performance. Every high-quality plastic mold costs higher and requires a … Read More

Are you a product developer and are you looking for a way to be cost-effective? The process that will not compel you to spend a lot to produce large numbers of parts is custom injection molding. However, if you are looking at a Return on Investment (ROI), your decision on which type of process to apply to manufacture large quantities of parts should depend on this because of the initial investment involved in the purchase of plastic injection molds. Below are the other things that you should know about custom injection molding.

Think about the quantity of parts that you need … Read More