Some factors affect plastic molds prices. Generally, the quality influences the cost. Plastic molds made in other countries are said to be cheaper (but not too cheap); however, these involve issues about quality and lifespan. High-production makers of plastic injection molds in the US make use of the finest quality in steel for cavities and mold base. More important, they use the most recent technology in CNC machining and work with expert tool makers who have sufficient knowledge and expertise in producing molds that meet the standards in the highest performance. Every high-quality plastic mold costs higher and requires a longer time to build – but it lasts longer and is easy to maintain.

Some factors affect plastic molds prices. Generally, the quality influences the cost. Plastic molds made in other countries are said to be cheaper (but not too cheap); however, these involve issues about quality and lifespan. High-production makers of plastic injection molds in the US make use of the finest quality in steel for cavities and mold base. More important, they use the most recent technology in CNC machining and work with expert tool makers who have sufficient knowledge and expertise in producing molds that meet the standards in the highest performance. Every high-quality plastic mold costs higher and requires a longer time to build – but it lasts longer and is easy to maintain.

Below are other elements that have an effect on plastic mold prices:

Quantity of cavities – Molds that make use of a smaller number of cavities in a mold undergo fewer tooling work and clearly cost less. However, plastic molds that were made by expert molders promote the highest level of efficiency because they have a maximum number of cavitations. Generally, molders create one plastic mold for each part. They do not support family molds because these will end up being substandard products and may involve more downtime brought by maintenance concerns.

Core Metal – To make way for shorter production runs (which will mean lesser production cost), some molders opt for molds that are made from aluminum. There’s nothing wrong with this, as long as you know that you will only make use of these plastic molds for a shorter span of time. However, if you are eyeing to use these molds for many years, using aluminum molds is not cost-efficient because these will only last a few years of use.

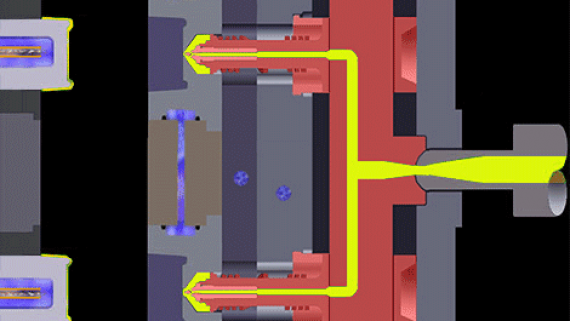

Core and Cavity Machining – All plastic injection molds must go through customization – cavities, cores, cooling lines and others. When steels are used in the tool, you can be certain that this will influence plastic mold prices because every plastic mold that is made of hardened steel requires a longer time to machine, aside from being expensive in the process. The benefit, however, is its longer lifespan.

Mold Base – This is also another factor that makes plastic molds prices lower or higher. When the material used in the mold base is steel (high-quality steel, to be specific) and the size is bigger than the usual, the cost is definitely affected. This is aside from the customization and machining requirements to meet the needs of a project.

Aside from these elements, part intricacy, and vertically integrated injection molders also create an impact on the plastic mold prices. However, why to dwell so much on the cost of plastic injection molds, when quality should be your foremost concern because of its tight tolerance and longer lifespan. If you know you can rely on an expensive material for a longer period, isn’t it more cost-efficient than buying a China-made plastic mold, which you can only use for a shorter amount of time? You should also practice caution when buying used a plastic mold. You may be able to save, but if you will not be able to use it for long, it’s not worth it. Think more about quality than savings because, in the long run, it is what should matter most.